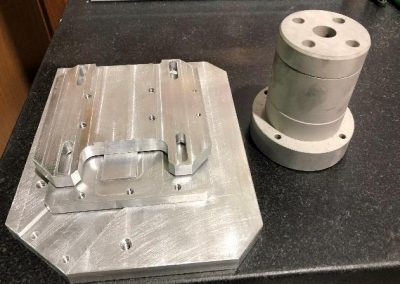

Mechanical Machining

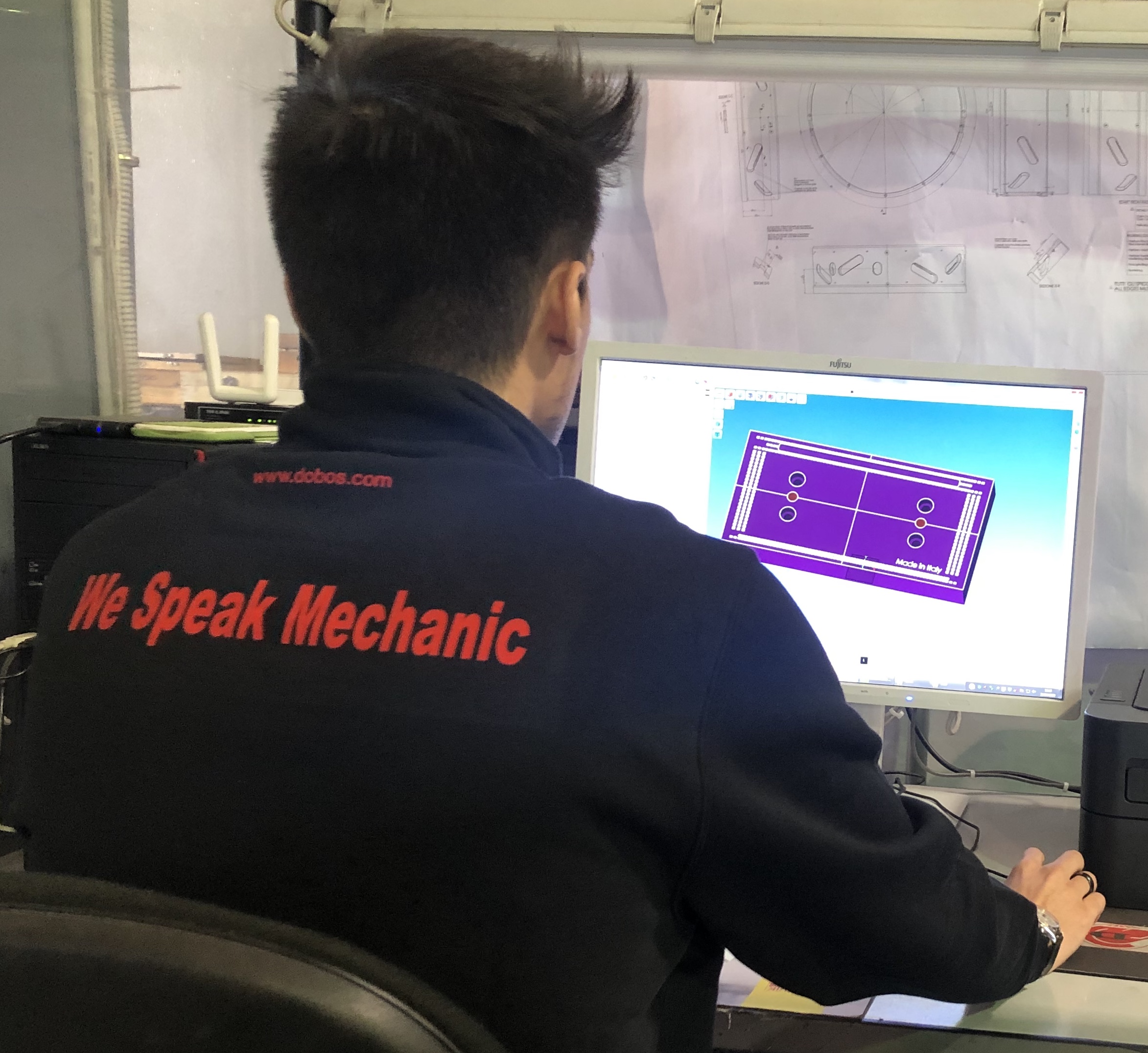

Processes the customer’s 3D files programming all the processing steps.

Our Machinery Fleet

Our technical department initially processes the customer’s 3D files programming all the processing steps. The CAD/CAM – WorkNC software allows us to offer a high quality and precision standard.

Once finished, the details are subjected to strict controls to verify compliance thereof by means of computer-interfaced precision digital instruments. Lastly, the details are identified using special Dobos labels so as to facilitate the customer.

Once finished, the details are subjected to strict controls to verify compliance thereof by means of computer-interfaced precision digital instruments. Lastly, the details are identified using special Dobos labels so as to facilitate the customer.

Below is our machinery fleet in the mechanical machining department:

- 2 AWEA BM1680 MACHINING UNITS

II. 1700x800x700 strokes

III. SELCA numerical control - 1 CERUTI BM 120 BORING MACHINE

I. 2000x1500x1500 strokes - 1 CERUTI BM 80 BORING MACHINE I. 1500x100x100 strokes

- 1 GUALDONI Universal MILLING MACHINE II. 1200x700x500 strokes

- 1 GUALDONI Universal MILLING MACHINE I. 800x400x500 strokes

- 2 WIRE WELDING MACHINES

- 2 OLMAC LATHES

II. 600×4000 turnable diameter

- 3 RADIAL ARM DRILLS

- 2 TANGENT GRINDING MACHINES

III. 800×400 strokes - 1 HURON 2000 6-Axis milling machine

IV. 2000x1500x1000 strokes

V. SELCA numerical control - 1 AERRE 4-Axis machining unit

I. 500x500x700 strokes

II. SELCA numerical control - Main digital control tool:

RUPAC HoptiHite altimeter

I. Measuring range: up to 915mm

II. Plane / hole repeatability: 0.003 / 0.005 mm

III. Resolution: 0.001 mm